From Sand to Sparkle: The Journey of Glass

Glass has long fascinated humanity with its remarkable clarity, versatility, and captivating beauty. Its creation involves transforming humble ingredients like sand, soda ash, and limestone into a molten substance that can be shaped and molded into various forms. Among its many applications, glass is particularly cherished in the world of jewelry-making, where it is transformed into dazzling beads that adorn necklaces, bracelets, and earrings. In this article, we will delve into the fascinating process of glassmaking and explore how glass beads are meticulously crafted for the purpose of creating exquisite jewelry.

The Art of Glassmaking:

The journey of glass begins with carefully selected raw materials, primarily silica sand, soda ash (sodium carbonate), and limestone (calcium carbonate). These ingredients are mixed together and heated in a furnace at temperatures exceeding 1,500 degrees Celsius. The intense heat melts the components, creating a molten liquid known as glass. To enhance its properties and appearance, various additives such as colorants and stabilizers can be introduced during the melting process.

Glass Bead Manufacturing:

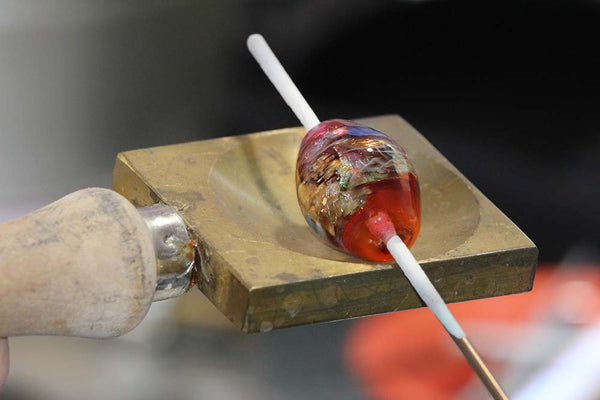

Glass beads for jewelry-making are created using a technique known as lampworking or torchworking. Some people refer to it as glassblowing, but that is just one of the techniques used in glassworks. Lampworking involves heating rods of glass in a high-temperature flame until they become malleable. The glass artist then manipulates the molten glass using tools such as tweezers and mandrels (metal rods) to shape it into intricate bead designs. Additional colors and patterns can be incorporated by melting colored glass rods and applying them to the surface of the bead.

Once the desired shape and design are achieved, the glass bead is placed in a kiln for annealing. Annealing is a crucial step that involves slowly cooling the glass to relieve internal stresses and increase its strength and durability. This gradual cooling process helps prevent the bead from cracking or shattering due to temperature variations. However, glass can still break if subjected to severe external forces, such as being dropped on a hard surface or experiencing a significant impact. While kiln-annealing strengthens the glass, it does not make it completely indestructible.

The Versatility of Glass Beads in Jewelry-Making:

Glass beads offer endless possibilities for jewelry designers. They come in a wide range of shapes, sizes, and colors, enabling artisans to create unique and personalized pieces. The transparency of glass allows light to pass through, resulting in a captivating play of color and sparkle. Moreover, glass beads can be faceted, etched, or coated with metallic finishes to add depth and dimension to the jewelry. Silver foil, mica, and shimmering goldstone are just a few of the elements that can be used in glass to create unique pieces.

Glass beads are often used as focal points in necklaces, bracelets, and earrings. They can be strung together with other beads, gemstones, or metals to create intricate patterns and designs. The vibrant hues of glass beads, combined with their smooth and lustrous surfaces, make them a popular choice for adding a touch of elegance and individuality to jewelry pieces.

Glassmaking is a remarkable fusion of science, artistry, and craftsmanship. From its humble origins as sand, glass undergoes a mesmerizing transformation into a molten liquid that can be shaped and molded into breathtaking jewelry beads. Through the skilled hands of artisans, glass beads are formed, annealed, and transformed into dazzling creations that adorn the bodies of individuals seeking to express their unique style and grace.

Whether adorning a statement necklace or delicately embellishing a pair of earrings, glass beads possess an innate allure that captivates the imagination. As the art of glassmaking continues to evolve and push creative boundaries, the possibilities for glass beads in jewelry-making are limitless, allowing us to embrace the beauty and versatility of this extraordinary material.